KARL HASSEL

Growing up in Norah Head on the Central Coast, NSW, Australia I was blessed to be exposed to pristine beaches and reefs, surrounded by surf culture from an early age. I immediately knew that surfing and everything related was what I wanted to dedicate my life to.

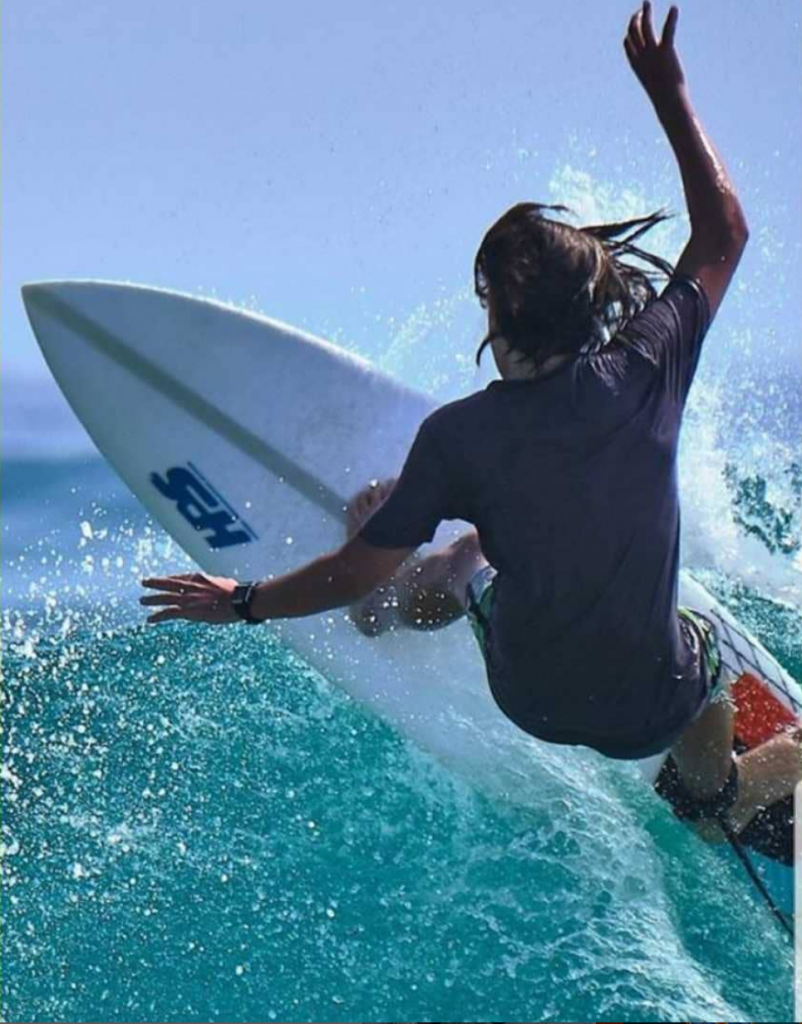

I shaped my first surfboard as a teenager, recycling old surfboards and reshaping them into something I could ride. This was the beginning of a lifelong passion for surfboard manufacturing. From there, I bought a polyurethane foam blank, from Brookvale in Sydney and hand shaped a surfboard. The surfboard shape was light and thinner than any other surfboard I had ever ridden. The new profile I had shaped completely changed my surfing experience enabling more dynamic manoeuvres, speed, and power. There was no looking back!

I have shaped for over forty years, through multiple generations and advancements in technology. I hand shaped for twenty-two years, then profiled for seven and now for the last fourteen years I have been using the latest CNC shaping machine in my purpose-built factory.

When you are purchasing a surfboard from HPS or Artifact, whether it be a fish, high performance board, long board, SUP (stand up paddle board) or foil, you are buying a lifetime of experience combined with the latest manufacturing techniques and highest-grade materials.

SPINE-TEK

Epoxy surfboard development has moved forward over the past several years with the introduction of a flexible part now commonly known as Spine-Tek. This part is built into the surfboards existing rocker profile providing increased drive to the surfboard, enabling manoeuvres to have extra speed and power.

This system was originally developed by me, Karl Hassel, with help from Len Hollaway from Shapers Australia. I constructed two epoxy surfboards with this technology. The first surfboard had two parts of the flex technology and the second had one with a unidirectional carbon fibre strip applied to the bottom of the surfboard. The flex to weight ratio achieved in surfboard number two was perfect resulting in manoeuvres with extra speed and power.

THE FACTORY

The factory is state-of-the-art using the latest techniques and machinery. There is plenty of room with a ground floor of over 250 square metres and mezzanine floor space of 220 square metres. The factory boasts a large shaping bay and ultraviolet laminating room. It also includes a large sanding space, painting room and polishing room to produce the high-performance surfboards.